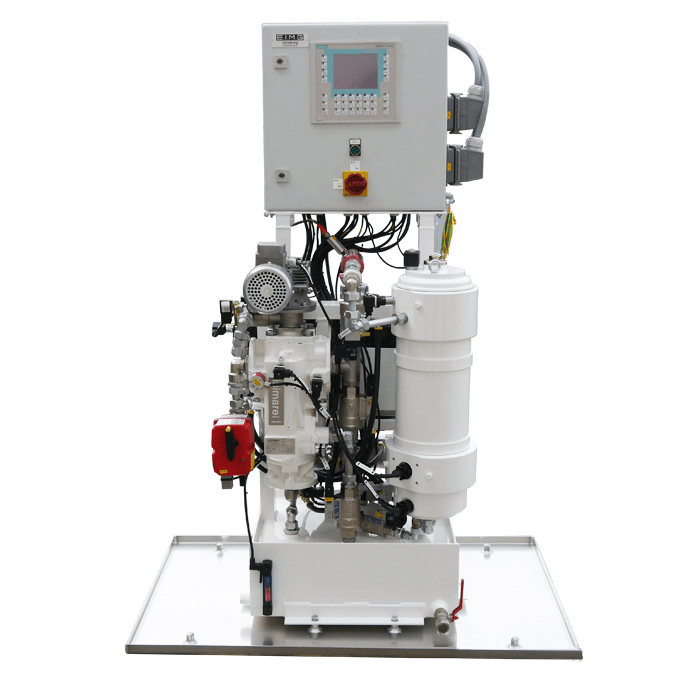

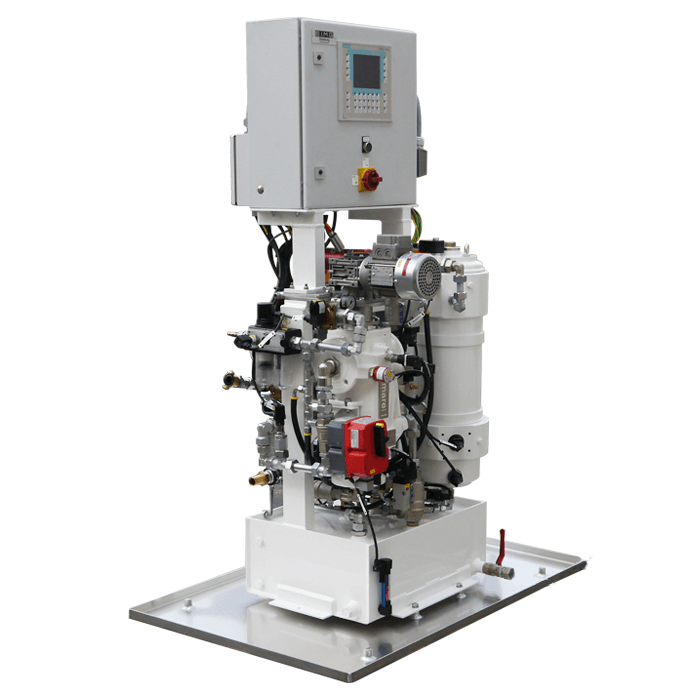

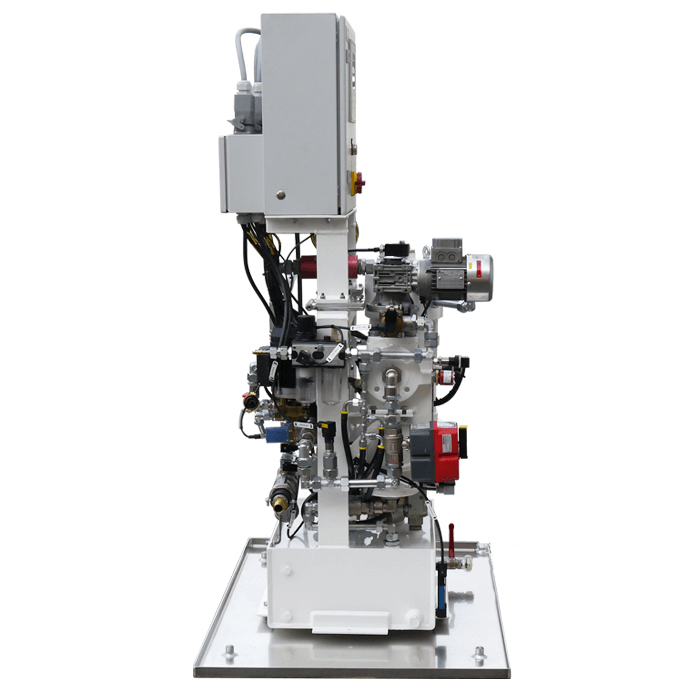

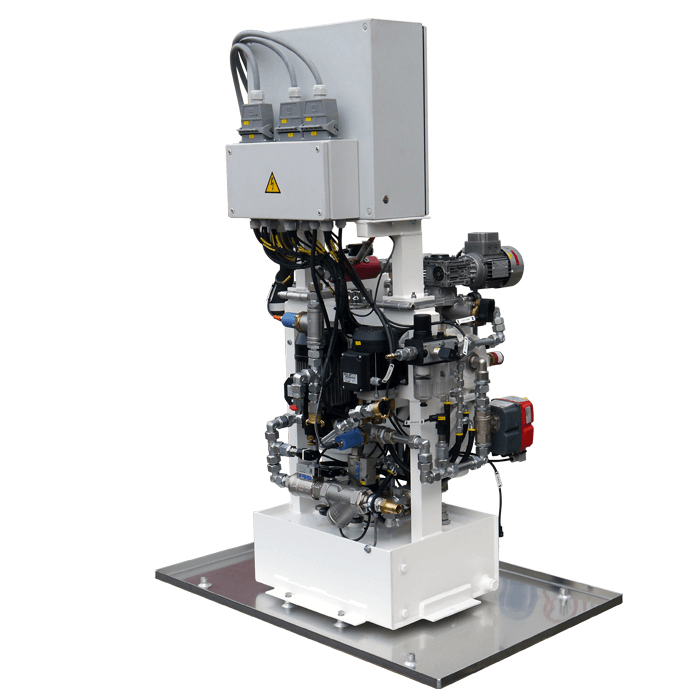

isimare. Fuel Filtration System ®

Our sustainable solution for the filtration of diesel fuel has been developed especially with regard to the various fields of application and real-world scenarios in which it ought to be used.

This is how our fuel filter system came into being. It meets the latest standards and even surpasses them by far.

Starting Point

- Diesel fuels, which are used in engines of locomotives and ships always contain foreign particles, mostly in the form of water droplets (also applies to EN-standard fuels)

- The majority of the foreign particles are already filtered out in the refinery, but particles smaller than 10 μm remain in larger numbers.

- During further handling and storage, the foreign particles accumulate again, primarily through the absorption of water.

- Therefore diesel fuel which is available at gas pumps and in storage tanks, therefore regularly contains large amounts of foreign particles.

Technical Description

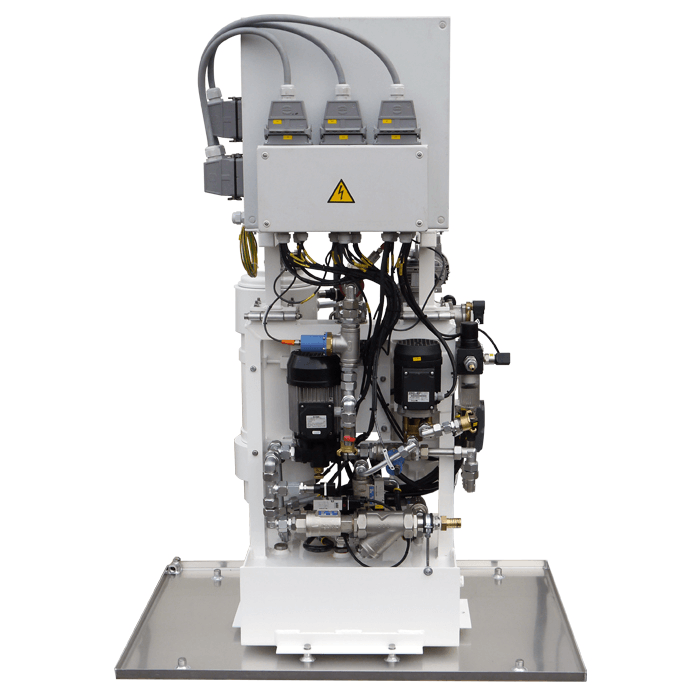

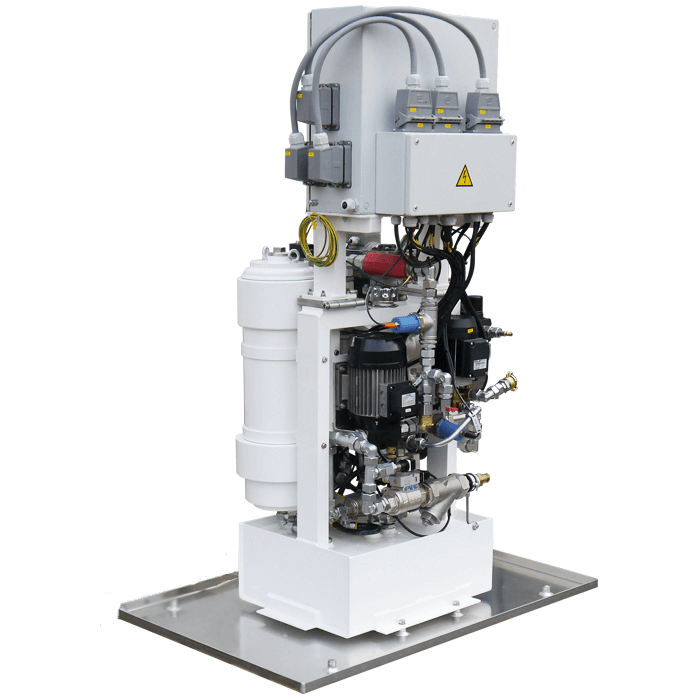

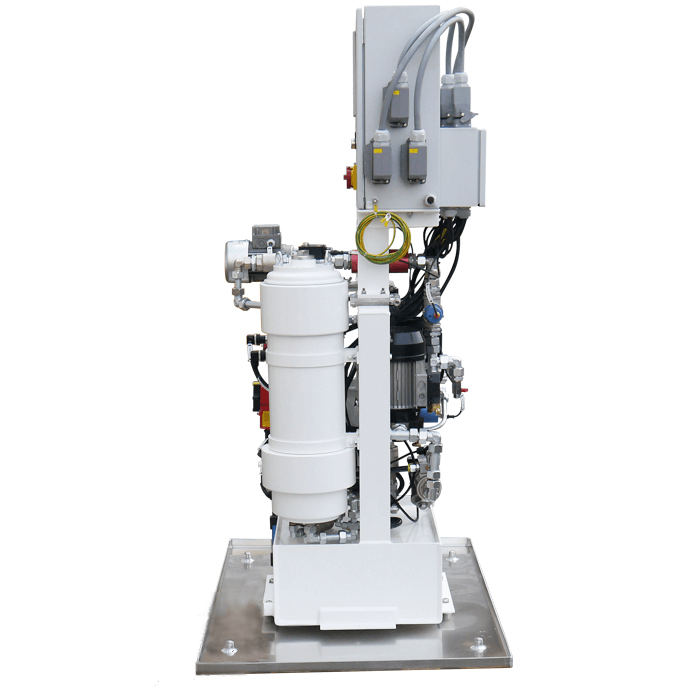

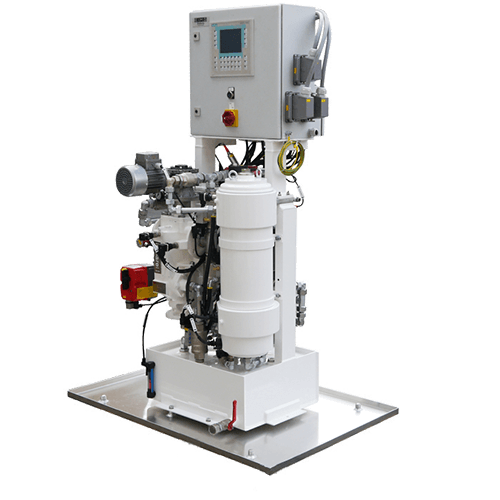

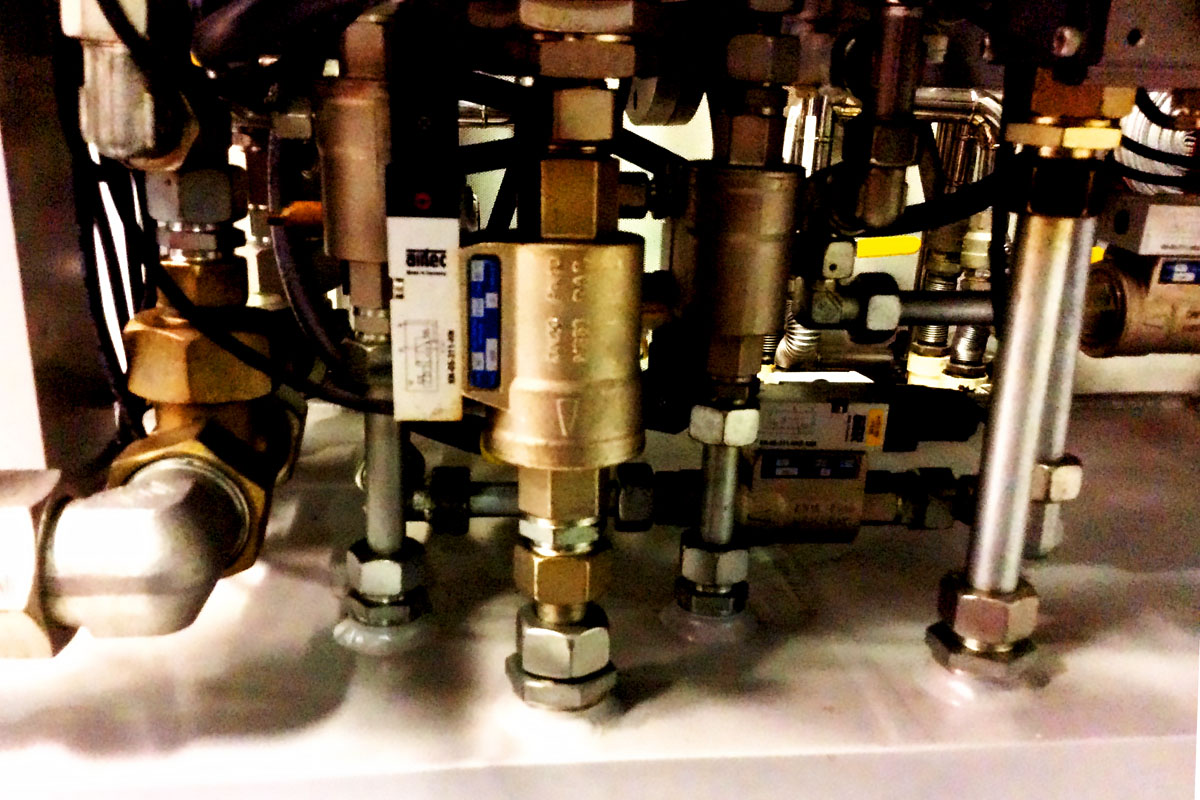

- The oil and fuel filter system is designed as an autonomous unit and has been optimized for energetic use. It essentially consists of:

- A supply line for oil and fuel and a fuel pump

- A first filter unit which contains a filter medium for separating particles from supplied fuel, the exclusion limit being between 12 μm and 4 μm particle size

- A second downstream filter unit, which frees the filtrate from particles and water, the exclusion limit is final for a particle size of 2 μm or less. At this point the filtrate is 99.9% freed of water

- A sludge tank with a drainage pump for separated material (water and sludge)

- The first filter unit comprises a backflushing filter with an integrated cyclone. The backwashing of the filter can be done environmentally friendly with compressed air.

- The second filter unit comprises, in addition to a particle filter, a coalescer filter for separating fine particles and water droplets from hydrophobic liquids. Coalescer filters have a fine washable filter fabric made of glass fiber (low maintenance costs)

- The fuel is returned to the process, water and sludge from the collecting tank can be disposed of separately

- Turbidifiers connected to the pipes provide information on the quality of the fuel supplied and purified.

Downloads

Technical Details

- Up to 9000 l/h (2400 gal/h)

- Standard and Individual sizes available

- European diesel fuel DIN EN 950

- United States Diesel fuel ASTM D975

- Russian diesel fuel GOST R 52368

- Japanese diesel fuel JIS K 2204

- Chinese diesel fuel GB252-2000 / GB19147